product description

Electroloy's EMCO # 515-307P no-clean solder paste is designed for lead-free soldering. It uses high shear resistance ingredients and provides excellent printing capabilities. This flux can withstand high preheat temperatures and does not change color. EMCO # 515-307 is specially manufactured for high-speed printing operations. EMCO # 515-307 provides excellent wetting and soldering on most circuit boards including OSPs, reducing solder ball formation and solder beads.

feature:

1.Excellent printing capabilities-for ultra-fine pitch welding operations

2.Relaxed reflow-process to increase production

3.Reduction of Tin Beads-Minimizing Rework

4.Welded Surface Formulation-IPC 7095 Voids Performance Class III

5.Excellent print-in-hole application-print, distribute SMT applications

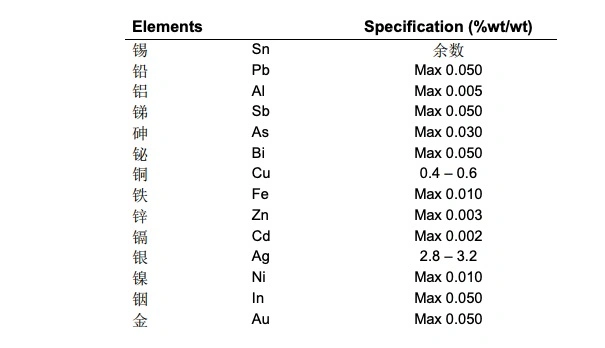

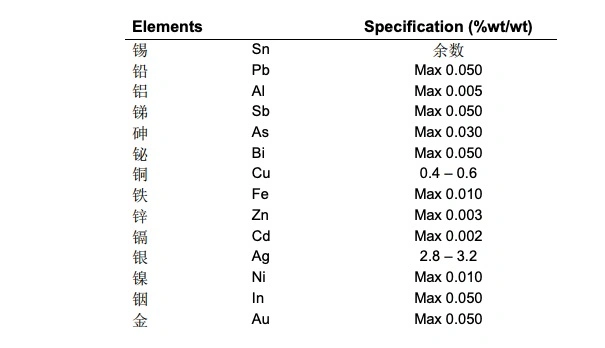

Chemical composition of the alloy

EMCO#515-307P lead-free tin wire is strictly controlled to the following LF-302 specifications:-

Appearance

Altolai's solder paste appears as a gray uniform solder paste.

Tin powder particles

The size of the solder particles is based on the international standard IPC J-STD-005.

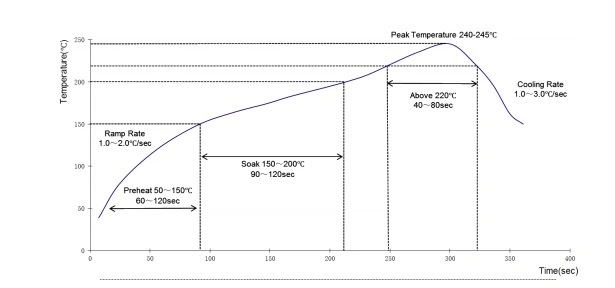

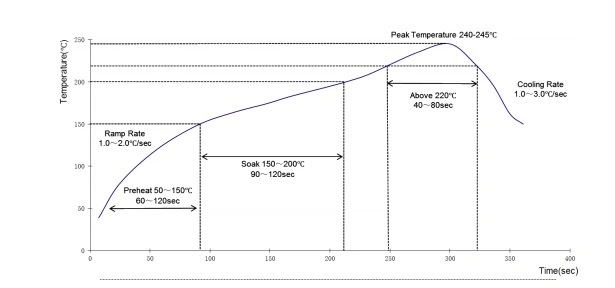

EMCO#515-307P Lead-Free Solder Paste Reflow Temperature Curve

Warm up

Heat from room temperature to 140-150 degrees Celsius at a rate of 1-2 degrees Celsius per second. Faster speeds can cause component rupture due to evaporation of adsorbed moisture.

Soaking zone

Between 150and 200 degrees Celsius. The soaking zone is used to level the temperature difference on the PCB. It is often used in PCBs with large differences in infrared furnaces and components and copper distribution.

Speed up to reflux

Maximum 2 degrees Celsius per second due to different thermal expansion rates inside the element.

Reflow

Peak temperature is related to component specifications. The peak temperature is between 240-245 degrees Celsius in 5-6 seconds, and is Above 220 degrees Celsius in 40-80 seconds.

cool down

Maximum 3 degrees Celsius per second due to different thermal expansion rates inside the element.

Clean

Misprints can be wiped with commercially available solvent cleaners

After cleaning, EMCO#515-307P residue can be left on the circuit board for reflow. If cleaning is required, a commercially available solvent cleaner can be used.

Stencil cleaning It is recommended to wipe with a commercially available screen cleaner wax paper.

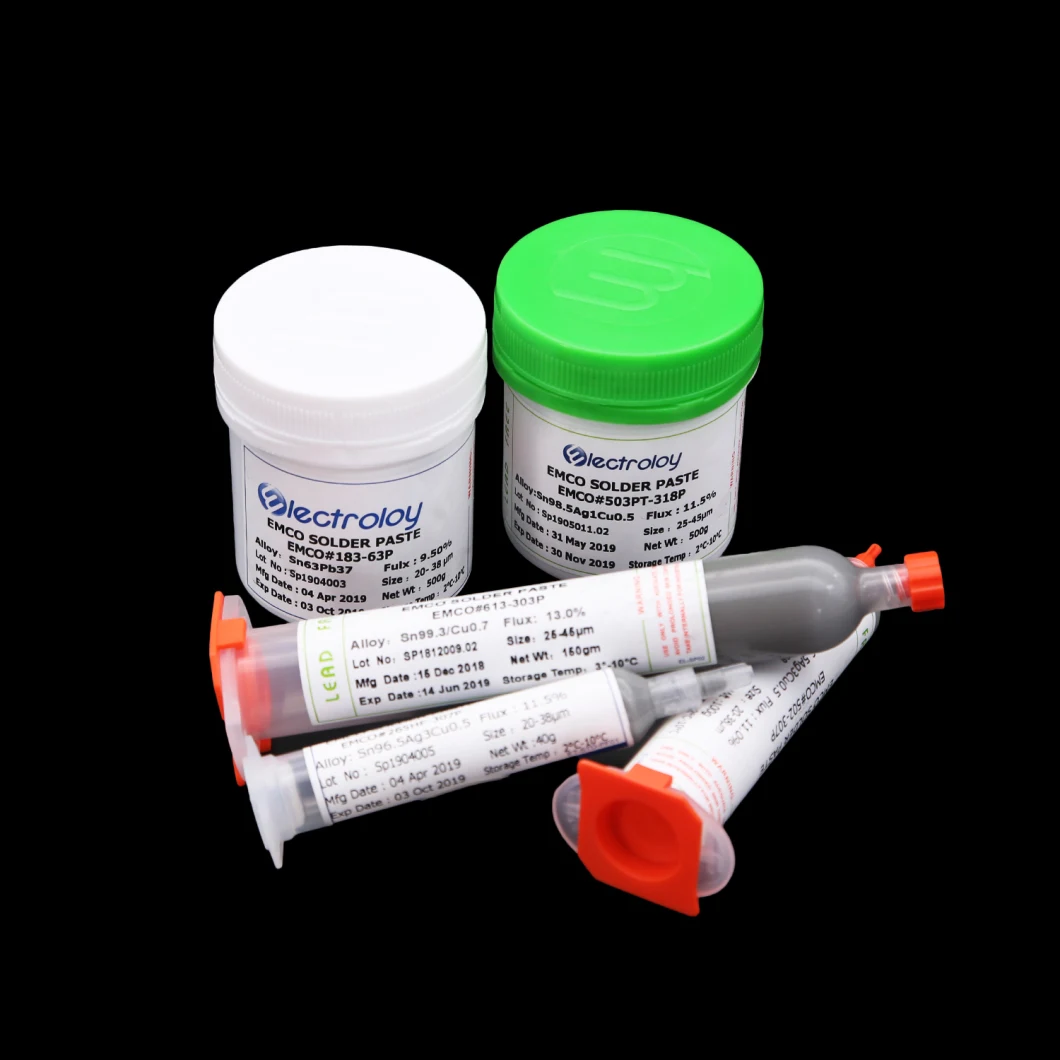

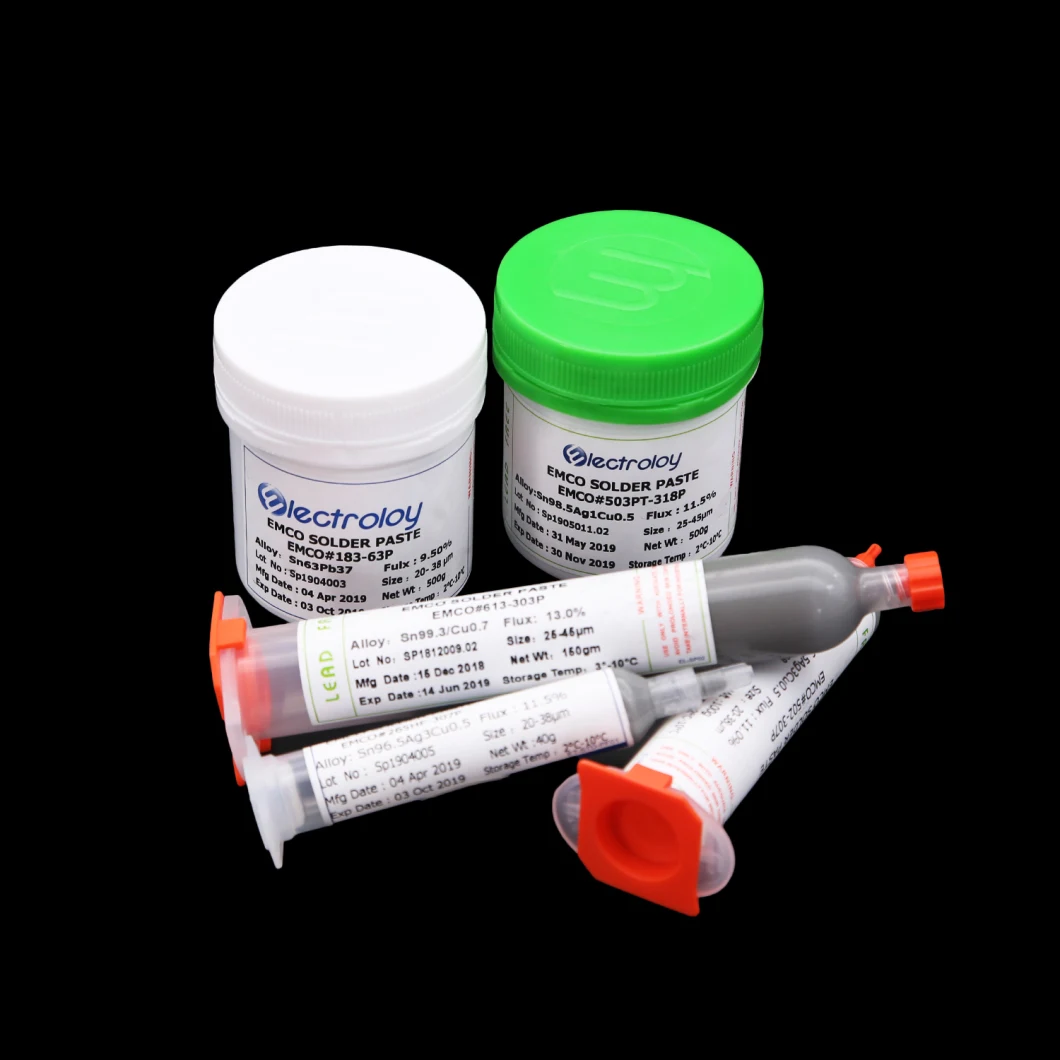

package

Each can of solder paste weighs about 500 grams and should be tightly sealed. The label should be accompanied by the product number, alloy composition, particle size, net weight and product batch

Related information. Solder tin cans should be placed in foam boxes and packed in cardboard boxes, each box weighing approximately 10 kg. Cartridge-type solder pastes of 600 or 1000 grams are available.

Storage and shelf life

Please store below 3-10 degrees Celsius. The validity period of the solder paste is within six months from the production date. Before using the solder paste, it needs to warm up for about 4 hours before use. Before putting the solder paste on the template, use a spoon to stir the solder paste for 1-2 minutes or the solder paste mixer for 30-60 seconds.

Ship

A certificate of analysis is attached to the shipment.

Material Safety Data Sheet

Product MSDS / SDS can be obtained from sales department.

Lead-free low-temperature alloys:

Lead-free medium temperature alloy:

Paste flux

Electroloy's EMCO # 515-307P no-clean solder paste is designed for lead-free soldering. It uses high shear resistance ingredients and provides excellent printing capabilities. This flux can withstand high preheat temperatures and does not change color. EMCO # 515-307 is specially manufactured for high-speed printing operations. EMCO # 515-307 provides excellent wetting and soldering on most circuit boards including OSPs, reducing solder ball formation and solder beads.

feature:

1.Excellent printing capabilities-for ultra-fine pitch welding operations

2.Relaxed reflow-process to increase production

3.Reduction of Tin Beads-Minimizing Rework

4.Welded Surface Formulation-IPC 7095 Voids Performance Class III

5.Excellent print-in-hole application-print, distribute SMT applications

Chemical composition of the alloy

EMCO#515-307P lead-free tin wire is strictly controlled to the following LF-302 specifications:-

Appearance

Altolai's solder paste appears as a gray uniform solder paste.

Tin powder particles

The size of the solder particles is based on the international standard IPC J-STD-005.

| weight in the sample% | Nominal size 3 | Nominal size 4 |

| Less than 1% of sample size | Greater than 45 microns | 38 microns |

| At least 80% of samples size | 45-25 microns | 38-20 microns |

| Up to 10% of samples size | Less than 20 microns | 20 microns |

EMCO#515-307P Lead-Free Solder Paste Reflow Temperature Curve

Warm up

Heat from room temperature to 140-150 degrees Celsius at a rate of 1-2 degrees Celsius per second. Faster speeds can cause component rupture due to evaporation of adsorbed moisture.

Soaking zone

Between 150and 200 degrees Celsius. The soaking zone is used to level the temperature difference on the PCB. It is often used in PCBs with large differences in infrared furnaces and components and copper distribution.

Speed up to reflux

Maximum 2 degrees Celsius per second due to different thermal expansion rates inside the element.

Reflow

Peak temperature is related to component specifications. The peak temperature is between 240-245 degrees Celsius in 5-6 seconds, and is Above 220 degrees Celsius in 40-80 seconds.

cool down

Maximum 3 degrees Celsius per second due to different thermal expansion rates inside the element.

Clean

Misprints can be wiped with commercially available solvent cleaners

After cleaning, EMCO#515-307P residue can be left on the circuit board for reflow. If cleaning is required, a commercially available solvent cleaner can be used.

Stencil cleaning It is recommended to wipe with a commercially available screen cleaner wax paper.

package

Each can of solder paste weighs about 500 grams and should be tightly sealed. The label should be accompanied by the product number, alloy composition, particle size, net weight and product batch

Related information. Solder tin cans should be placed in foam boxes and packed in cardboard boxes, each box weighing approximately 10 kg. Cartridge-type solder pastes of 600 or 1000 grams are available.

Storage and shelf life

Please store below 3-10 degrees Celsius. The validity period of the solder paste is within six months from the production date. Before using the solder paste, it needs to warm up for about 4 hours before use. Before putting the solder paste on the template, use a spoon to stir the solder paste for 1-2 minutes or the solder paste mixer for 30-60 seconds.

Ship

A certificate of analysis is attached to the shipment.

Material Safety Data Sheet

Product MSDS / SDS can be obtained from sales department.

Lead-free low-temperature alloys:

Alloy number | Alloy composition | Fuse | Feature | Application |

| LF-302 | Sn42 / Bi58 | 138°C | Reasonable shear strength and fatigue resistance. | Can be used for temperature-sensitive parts and LED welding operations.Can be used for multi-step welding and fuse-like fuses operations can also be used for nozzle and exhaust valve operations. |

| LF-329 | Sn42 / Bi57/Ag1 | 139°C | The addition of silver enhances its mechanical properties, with excellent resistance to thermal fatigue. | |

| LF-323 | Sn64 / Bi35/Ag1 | 170-190°C | The addition of silver enhances its mechanical properties, with excellentresistance to thermal fatigue. | |

Lead-free medium temperature alloy:

Alloy number | Alloy composition | Fuse | Feature | Application |

| LF-307 | Sn96.5 / Ag3.0 / Cu0.5 | 217-219°C | Excellent mechanical properties and thermalfatigue performance. | Standard SAC alloy for most SMT applications. |

| LF-315 | Sn99 / Ag0.3 / Cu0.7 | 216-228°C | Excellent mechanical properties and thermal fatigue performance. | Low cost SAC alloy for most SMT applications. |

| SN100C | Sn99.3/Cu0.6/Ni+Ge | 227°C | Excellent mechanical properties, bright and smooth solder joints.Excellent through-holesoldering performance. | SnCu alloy instead of SAC alloy for most SMT applications. |

Paste flux

Alloy number | Feature | Flux classification |

| EM#502 (HF) | Halogen-free flux, with high shear strength and excellent printing ability.Can also be used for high-speed printing operations.Its flux can withstand high preheat temperatures, which show excellent wetting on most circuit boards, leaving only clean residue. | ROL0 |

| EM#503PT (HF) | Halogen-free flux, with high shear strength and excellent printing ability.Has excellent anti-collapse performance and excellent adhesion performance.Its flux can withstand high preheat temperatures, which show excellent wetting on most circuit boards, leaving only clean residue. | ROL0 |

| EM#615 | Specially configured flux with excellent printability for ultra-fine pitch welding operation.Its flux can withstand high preheat temperatures and a wide range of operational reflow jobs.It shows excellent wetting on most circuit boards. | ROL1 |

| EM#233 | Specially configured flux enhances activity on difficult-to-solder circuit boards and parts.Has excellent anti-collapse performance and excellent adhesion performance.It shows excellent wetting on most circuit boards and leaves only clean residue. | ROL1 |

| EM#255 | Specially configured flux enhances activity on difficult-to-solder circuit boards and parts.It shows excellent wetting on most circuit boards.Has excellent anti-collapse performance and excellent adhesion performance.The residue is soft, non-sticky; can be operated on probe test.Residues are clean, printing takes longer and productivity increases. | ROL1 |

| EM#265 (HF) | Halogen-free formulations, temperature range can be widely used, printing operation for a long time.Soft, non-stick residue enhances reliability during in-circuit testing and reduces test probe cleaning frequency.Has excellent anti-collapse performance and excellent adhesion performance. | ROL0 |