flux coating 40% Silver brazing strip/rods for brazing steel and stainless steel

Specifications

silver welding rods are silver or silver base solid deep body electrode, has good process

performance,Low melting point, good wettability and the ability to fill the gaps, and high

strength, good plasticity, good conductivity and corrosion resistance, can be used To

brazing in addition to aluminum, magnesium, and other low melting point metal all ferrous

and non-ferrous metals.

1. silver solder material include silver solder rod,wire,plate,ring,ribbon-like filament,powder ect

2. environmental silver solder material(with cadmium) and no-enviromental silver solder material

(without cadmium).

3. common grades are 5%Ag,10%Ag,15%Ag,20%Ag, 25%Ag,30%Ag,35%Ag,40%Ag,45%Ag ect.

4. the price is floating according the raw silver material.pls confirm the price when you make the order.

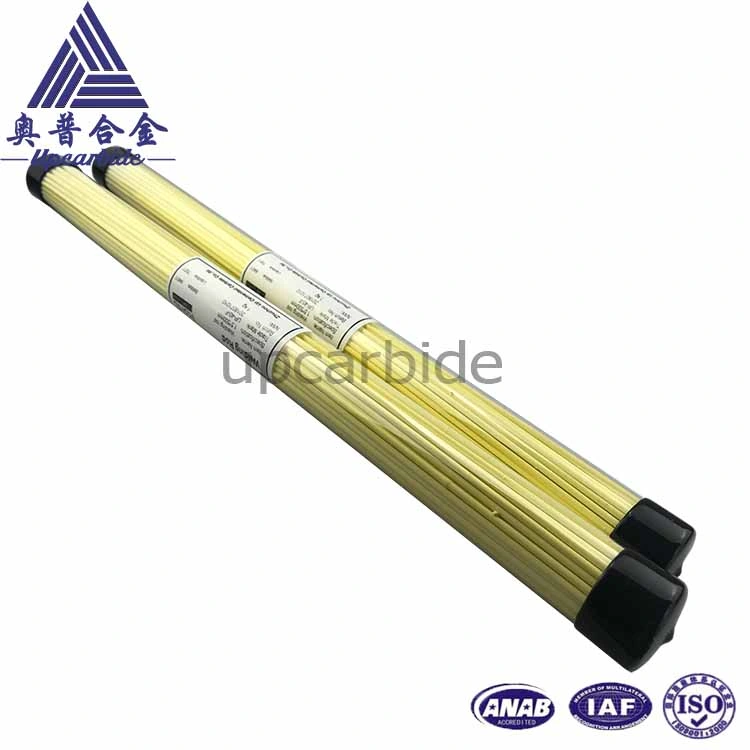

5. package: 1kg/plastice ,Vacuum packaging, prevent oxidation..

flux coating 40% Silver brazing strip/rods for brazing steel and stainless steel

1. Conposition of rod: Ag-40%,Cu-30%,Zn-28%,Sn-2% (environmental material)

2. the flux coated material is fluoride and boron.

3. diameter: the rod diameter is 1.5mm, with flux coated ,the diameter is about 2.5mm. length no change.

4. inner package: 1kg per plastic tube.

5. outer package: 10kg each carton , 2 cartons, gross weight is about 20.8kg.

Specifications Show

Different between environmental silver solder material(cadmium free) and no-enviromental

silver solder material(with cadmium):

1.enviromental silver solder material(without cadmium):

it is enviromental solder material,no toxic.

2.No-environmental silver solder material(with cadmium):

the cadmium(CD) can Lower melting point, increase liquidity in the solder, it is toxic,some countries

restrict imports.mexico,Africa can use it.

silver welding rods' grades and specifications:

1.enviromental silver solder material(without cadmium):

| Item Number | National Standard | Chemical Compositions(%) | melting temperature ( ºC) | Strength (MPa) | electrical resistivity (*10¯4 Ω·m) | Advantages and Usages | ||||

| Ag | Cu | P | Sn | other | ||||||

| FC-CuP | BCu93P | rest | 6.8~7.2 | / | / | 710-800 | 470 | 0.28 | brazing mechanical and electrical products, copper, brass brazing small gap | |

| FC-Cu94P | BCu94p | / | rest | 5.8~6.2 | / | / | 710-890 | 441 | 0.25 | Low liquidity, the most suitable resistance brazing |

| FC-CuPSn | BCu91PSn | / | rest | 5.8-6.2 | 3.5 | / | 640-670 | 560 | 0.32 | Good flow properties, joint performance is equal to FC-Ag25CuZn's |

| FC-Cu86PSnNi | BCu86PSnNi | / | rest | 5.1-5.5 | 7.5 | Ni1 | 620-670 | / | / | Good flow properties, joint performance is equal to FC-Ag25CuZn's |

| FC-Ag2P | BCu91PAg | 1.8-2.2 | rest | 6.8-7.2 | / | / | 645-780 | / | / | brazing refrigerators, air conditioning, electrical, instrumentation, optical and other products |

| FC-Ag5P | BCu89PAg | 4.8-5.2 | rest | 5.8-6.2 | / | / | 650-800 | 519 | 0.23 | have a very good solder plasticity, good conductivity, low liquidity, for brazing a larger gap between parts |

| FC-Ag2PNi | BCu89PAgNi | 1.8-2.2 | rest | 6.8-7.2 | / | Ni2 | 643-788 | / | / | brazing mechanical refrigeration, airconditioning, musical instruments, glasses and other products |

| FC-Ag15P | BCu80PAg | 14.5-15.5 | rest | 4.8-5.2 | / | / | 640-802 | 503 | 0.12 | brazing air conditioning, vehicles, shipbuilding, chemical machinery and switch connector |

| FC-Ag25P | BCu70PAg | 24.0-26.0 | rest | 4.8-7.2 | / | / | 650-710 | / | / | have very best plastic solder, conductive best for high request electrical connector brazing |

2.No-environmental silver solder material(with cadmium):

Silver welding rods' storage methods:

1. The silver welding rod cases: the warehouse where the silver electrode in a dry and ventilated environment

should possess, avoid damp;Refused to water, acid, alkali liquid, such as easy to volatilize Corrosive material

existence, more unfavorable coexist with the material to the same warehouse.Electrode should be placed on

the wooden pallets, not to be, or directly on the floor Close to the wall.Access and handling electrode with.

2. Be careful not to break the packing, especially the inner packing "heat shrinkable film."Open the silver

electrode packing should be finished as soon as possible to use it all(within a week), once the welding wire

is directly exposed to the air, the anti-oxidation will greatly shorten the time (especially in the wet and

corrosive mediumThe environment.

3. According to the principle of "first in first out" electrode, as far as possible to reduce product inventory time.

Please according to the electrode type, specification, classification storage, to prevent misuse.

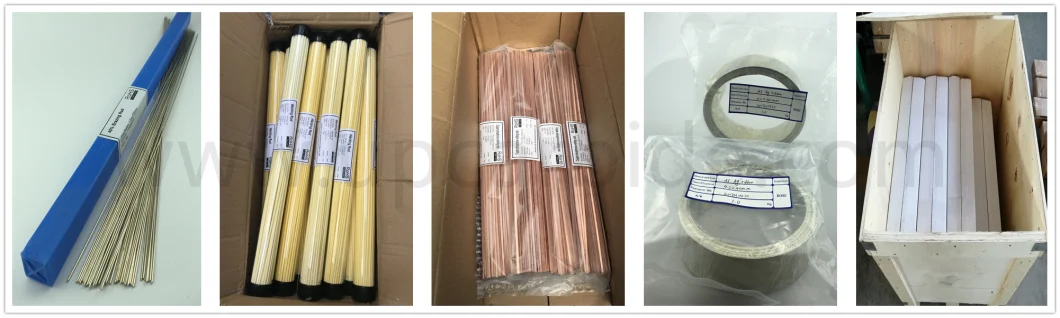

Packing details

Shipping ways

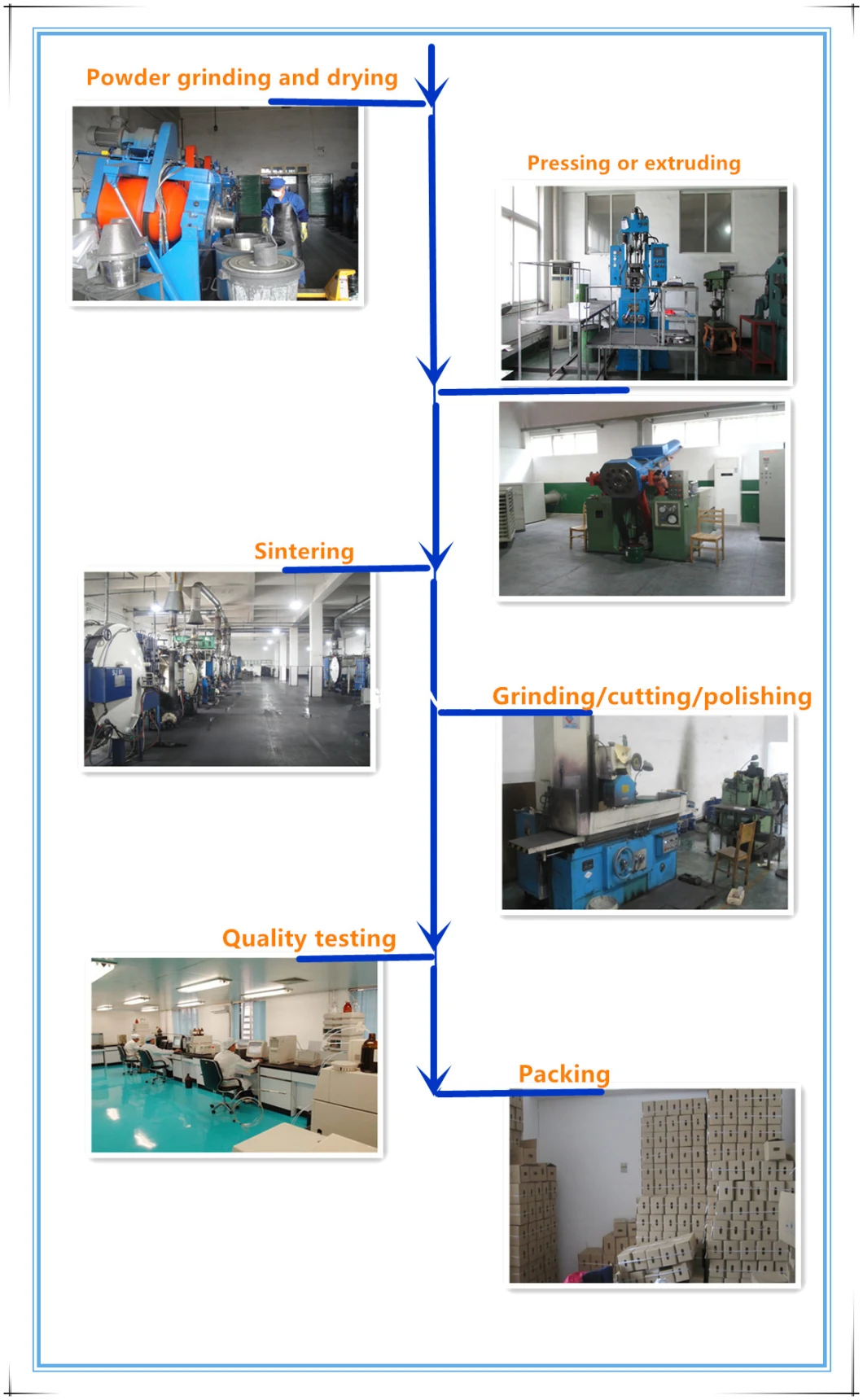

Production process

Contact details